Breathable Films

Breathable Films

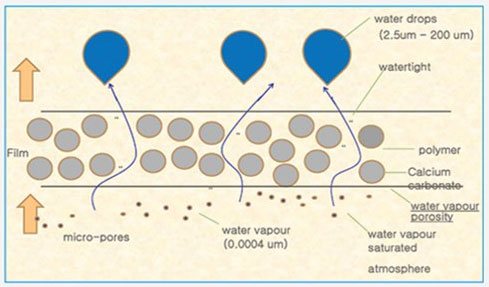

'Tec Line' Breathble Films are manufactured from compunded polythylene by the extrusion technology. The films are permeable for gases and water vapors but impermeable to water in liquid state. Suitable for hygienic application, the films are designed for use in the manufacture of disposable sanitary products Baby Diapers, Sanitary Towels, Incontinences Pads and supplies for the chronically ill.

The films help to enhance user comfort-their permeability allows the skin to breathe better, reducing potential occurrence of undesired side effect such as skin rash, sores etc.

Product advantages

- Adjustable breathability

- Light weight & soft touch

- Good mechanical strength

- Good adhesion to non wovens and fabrics

- Custom-made backsheet

PROCESSED MATERIALS

PE (polyethylene) is the most frequently used plastic in the world. Its annual production exceeds 90 million tons. It was developed in 1933. This invention was essential for the development of modern plastic materials, which we cannot imagine our life without anymore. From the chemical point of view, the polyethylene structure is very simple, therefore it can be produced relatively in an easy and inexpensive way. According to its density, polyethylene is classified into two major types, so-called low-density (LDPE) and high-density (HDPE), the third type is the so-called linear low-density PE (LLDPE).

Both PE types can be processed easily using plastic-processing technologies, and manufacture products of various shapes and sizes from them. In general, polyethylene has an excellent strength, high toughness, and ductility; products may be transparent or coloured with pigments. The common PE processing method is extrusion (2D products) and injection moulding (3D products).

The best-known polyethylene applications include:

- Flexible packages – bags for fresh and frozen food products, shopping bags, extensible foils.

- Solid packages – bottles for detergents and cosmetics, cans, barrels, large-size containers.

- Daily need products – minor kitchen dishes.

- Tubes and pipes

Polyethylene may be recycled. It is widely present in the communal waste, therefore there are efforts to sort it (yellow container for sorted waste) and reuse.

APPLICATION AREAS

- Use as backsheet in various hygiene products:

- Baby diapers

- Sanitary napkins

- Incontinence pads

- Adult diapers

- Means for the chronically ill

- Various medical applications

Functions

SPECIFICATIONS

Parameters:

- Width: 80 – 2,000 mm

- (GSM) Square weight: 15 – 80 g/m².

Breathability:

- In a range of 500– 5000 g/m² within 24 hrs

- Micro Embossing.

- Possibility of applying anti-microbial treatment.

- Corona treatment option.

Printing options:

- The colour of the film depends on your requirement.

- Flexographic print up to 4colours.

Optional Properties:

- Tensile Strength

- Water Vapor Transmission Rate (WVTR)

- Elongation

- Coefficient of friction (COF)

- Gloss

- Opacity